SWIFT AUXI TECHNIK P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SWIFT AUXI TECHNIK P.LTD.

Screw Doser

Volumetric Dosers

SD series volumetric dosers are suitable for auto - proportional mixing of new materials, regrinds, masterbatch or additives. A Micro Stepping motor is used in this series. According to the set mixing proportion, the PLC accurately controls rotation of the high precise dosing screw to squeeze out materials with an accuracy of ±1%. A Micro Stepping motor is coupled to a dosing screw of 12, 16 or 18 mm diameter to give a total of Three models with output. ranging from 0.1-32 kg/hr. Double color dosers can be assembled from two single color dosers if required.

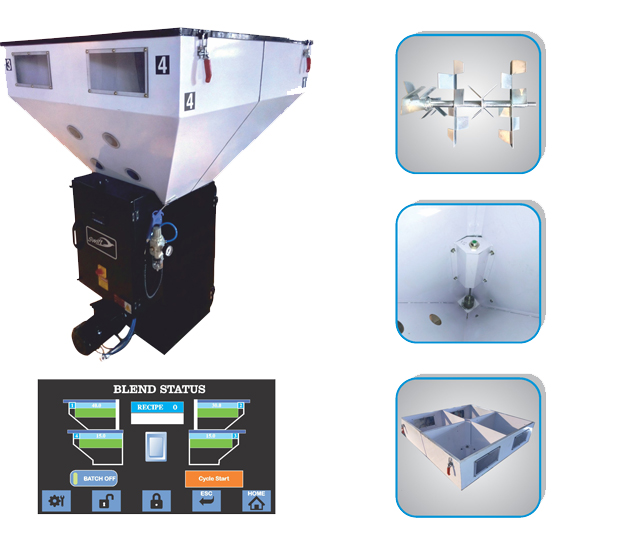

Gravimetric Blender

Unique Features

Spot-on accuracy - Blend accuracy to 'A of 1%

Repeatable, consistent performance job to job

Simple to use touch screen control

Quick recall recipes gives repeatability you need

Improved accuracy on lower dosing percentages

Fast accurate response times

Enhanced algorithms provide better weight reading accuracy

Diagnostic screen display target set-point percentage and actual percentage dispensed

Precision ratio control - all components

Instantly see your materials usage

Set and save 1000 different recipes

Simple component setup

Three different levels of password protection

Full color graphics aid usability

A completely sealed, welded steel chassis eliminates pellet leakage

Hopper Extrusion Controller

Engineered as part of the SWIFT true weigh gravimetric extrusion control system, the true weigh hopper measures the mass flow of material into the extrusion process and sends this loss in weight information to the true weigh controller. The controller then accurately monitors or adjusts the extruder screw and / or haul off speed to maintain consistent yield control. This enables an operator to run a uniform product within the tightest tolerances at the lowest possible cost.

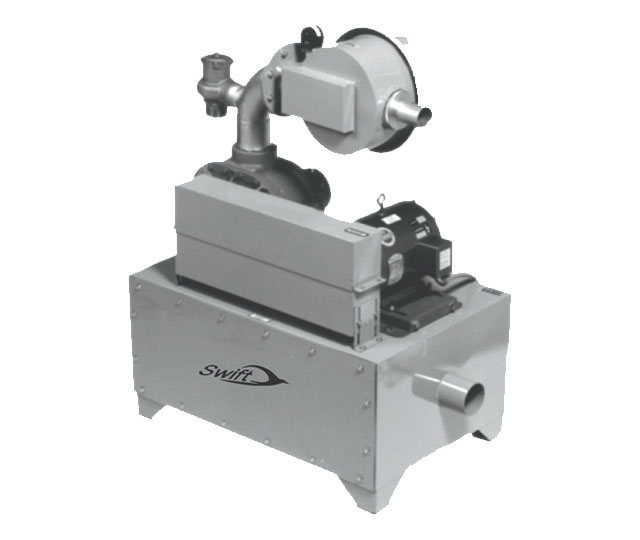

Grinder And Granulator

High speed Granulator

The device is applicable to centralized of all kinds of plastics, including the waste of injection moulding, blow molding and extrusion forming. The structure of crusher is compact for convenient operation, easy cleaning and maintenance which enhances the working efficiency.

Note :The Grinding capacity depends on the diameter of screen mesh.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

55501.jpg)